Sewage Treatment Plant

Sewage Treatment Plant (STP)

Sewage treatment is a wastewater treatment process to remove contaminants from wastewater to produce an effluent that is suitable for discharge to the surrounding environment or it can be reuse in various application, thereby preventing water pollution from raw sewage discharges.

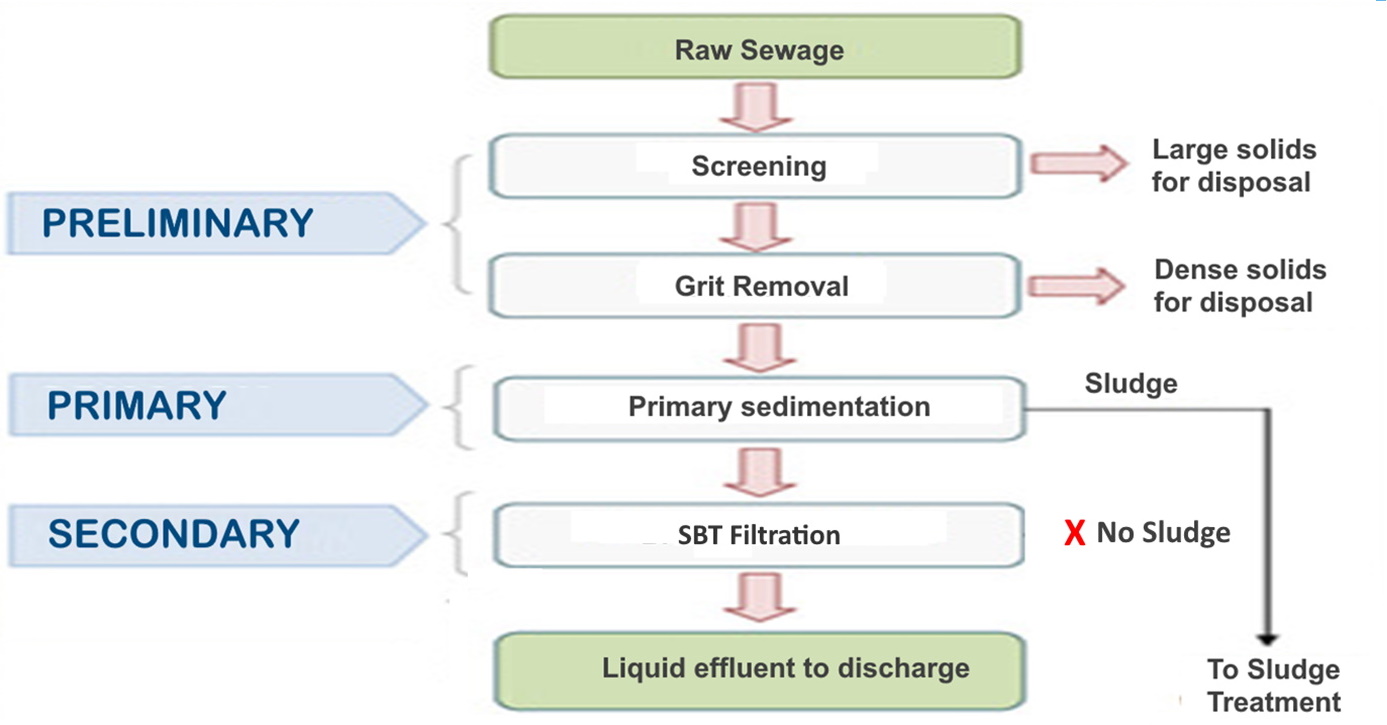

Sewage treatment can be done in three phases:

1) Preliminary (screening & grit removal) for removal of some bulky solids like paper, plastics, sand etc,

2) Primary (Sedimentation) for removal of some light organic matter, and

3) Secondary (SBT Filtration) for Bacterial decomposition.

SBT for Sewage Treatment Plant (STP)

Soil Biotechnology (SBT) has profound application in the domestic sewage recycling.It has more than 200 installations across India. It has been working with Military Engineering Services, Air ports, various Jal Boards, PHE, Jal Nigam etc.SBT has been adopted by Government of Maharashtra for its ambitious Rural Sanitation scheme. Similar on the line it is under consideration with various other state governments for implementation of their rural sanitation programme.

Process Flow & Description

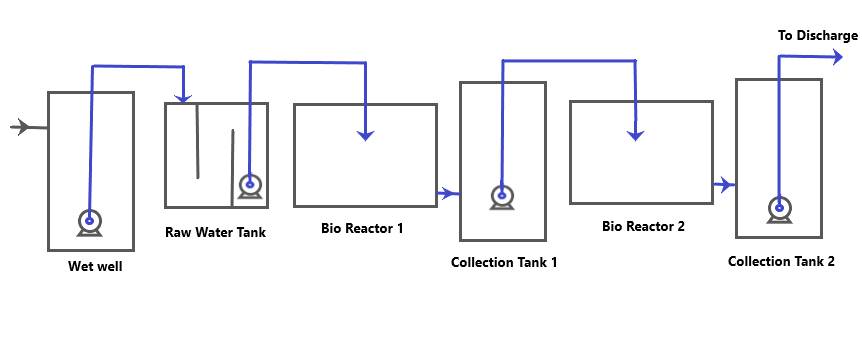

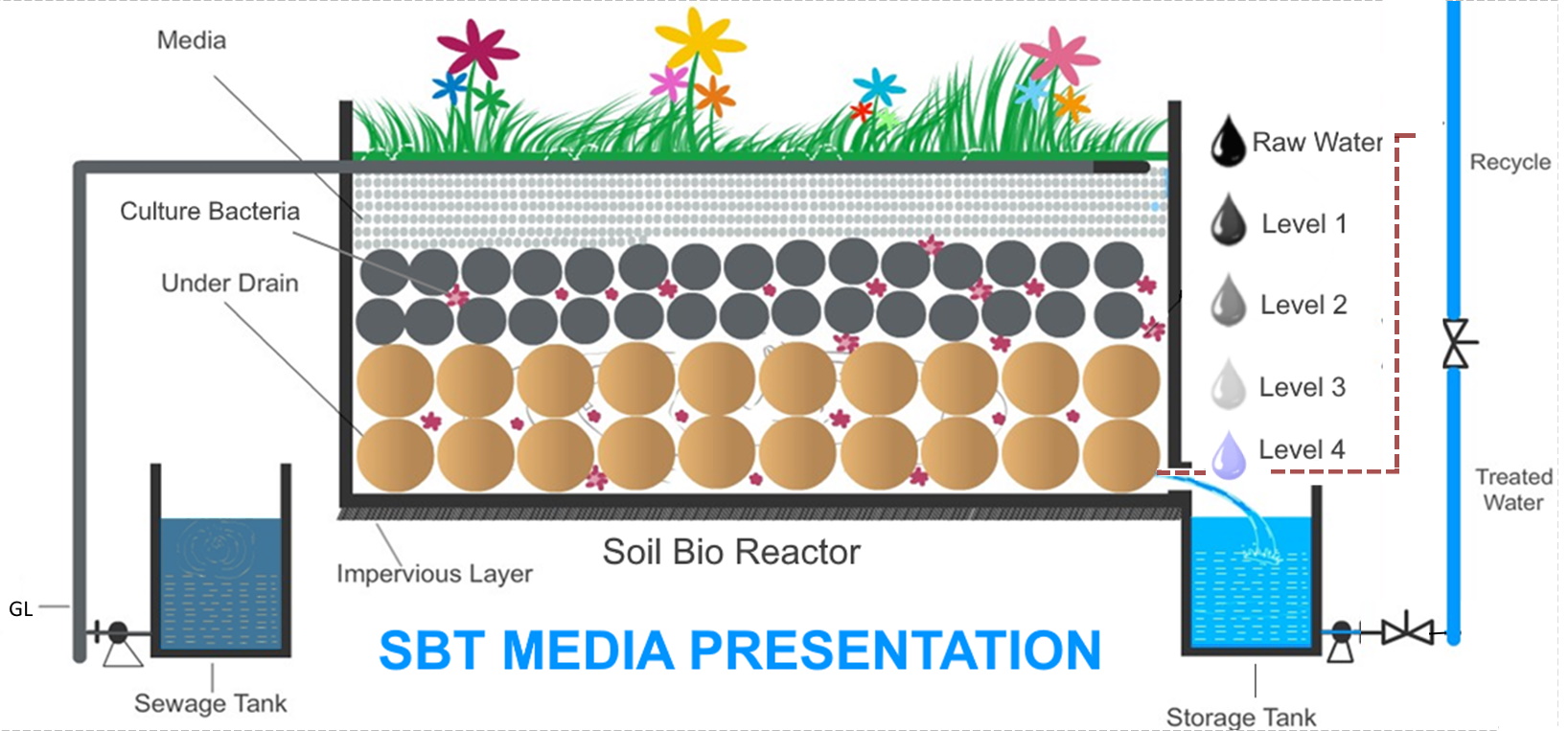

SBT systems are typically housed in RCC, stone-masonry or soil bunds and consists of an impervious containment.It starts with a under drain layer, above which lies a layer of media housing culture and bio-indicator plants.Water first passes through the additive layer and subsequently passes through the media.The process can be run as single stage or multistage depending on water quality desired. Raw sewage is collected in Raw Water Tank (RWT) after initial screening and settling.

The raw sewage is pumped on the top of a SBT Bio Reactor where it percolates through a geological media. The treated water from BR-1 is collected and again treated to attain reuse quality and then collected at the bottom of the Bio-Reactor (BR-2) and stored in a Treated Water Tank (TWT). Distribution of wastewater over the media is achieved via pumping, piping and distribution arrangements. Solids are typically retained in the settling tank and then can be removed mechanically. Water first percolates through the bioreactor media which in houses cultured media in 30-35 min and gets collected into the collection tank.

Why SBT for Sewage Treatment

Green technology with green chemistry

No chemical usage

No secondary biosludge generation

Delivers zero liquid discharge compliances

No requirement of Tertiary treatment

No GreenHouse Gas emissions like others

No maintenance during breakdown period; practically can run on zero loading

Simple to operate and maintain, no skilled man-power required

Requires very low energy to operate compared to its counterpart

Low operating cost compared to operating technologies in the market

Low operating cost compared to operating technologies in the market

High order of BOD, COD, suspended solids,color, odor & ammonia removal

Provides secondary and tertiary treatment all in one unit.

Solution can be ideally decentralized and self sustaining.

Designed as per Area/ Space availability (Multi tower design available)